Products

Featured products

Contact Us

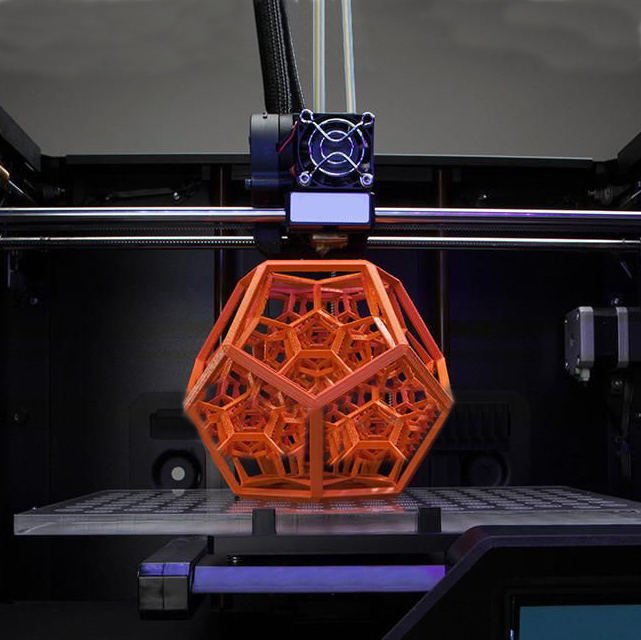

- 3D PRINTER

- China

- 2023-08-06

- Mass supply

Applications

6063 aluminum is commonly used in extrusion production for architectural applications, interior, and exterior decoration industry. Such as window frames, door frames, curtain wall frames, railing, fencing, decking, furniture. Aluminum alloy 6063 is also the most popular alloy for many industries where high strength is not an essential factor for the product.

Chemical Component

Mg and Si are the main alloying elements for 6063 aluminum. The alloy composition of 6063 is as below.

| Si | Fe | Cu | Mn | Mg | Cr |

|---|---|---|---|---|---|

| 0.2-0.6 | 0.35 | 0.1 | 0.45-0.9 | 0.1 | 0.45-0.9 |

Mechanical Properties

6063 aluminum is a medium-strength heat-tremble strengthening alloy in the AL-Mg-Si system. It is with the advantages of excellent processing properties, weldability, extrudability, and good corrosion resistance. It is a typically alloy for extrusion process. Applications requiring higher strength usually use 6061 or 6082 instead.

The mechanical properties of 6063 aluminum depend significantly on the temper or heat treatment of the material. The most common tempers for this alloy alloy are:

T5 Condition: Cooled from an elevated temperature and artificially aged.

T6 Condition: Solution heat-treated and artificially aged.

| Aluminium Alloy & Temper | Thickness mm | Tensile Strength Rm/Mpa | Yield Strength Rp0.2/Mpa |

|---|---|---|---|

| 6063-T5 | <3.0 | 175 | 130 |

| 6063-T5 | <3.0 | 175 | 130 |

| 6063-T5 | <3.0 | 175 | 130 |

Features

1

Thinner aluminium round tube, the thinner thickness item.2

Thinner round tubes can be standardized.3

This thinner round tube has better quality.4

Intelligent model engine simplifies usage process5

Standard color for standard this thinner aluminium round tube.6

Thinner thickness for this thinner aluminium roller tube.7

Customized color for this thinner aluminium roller tube.8

Irregular cutting of parts by model cutting

Product-color-scheme.pdf

Product-color-scheme.pdf