Researchers in the United States and Germany have developed a new 3D printing process that can produce nanoscale quartz glass products at relatively low temperatures, with the potential to directly print optical glass components on semiconductor chips.

This new process was jointly developed by the Karlsruhe Institute of Technology in Germany and the University of California Irvine in the United States. Researchers used an "organic-inorganic hybrid" material - cage polysilasesquioxane (POSS) as the printing material. The core of POSS molecule is an inorganic "cage" composed of silicon and oxygen atoms, with some organic functional groups connected outside. Functional groups are atoms or atomic groups that determine the chemical properties of organic compounds.

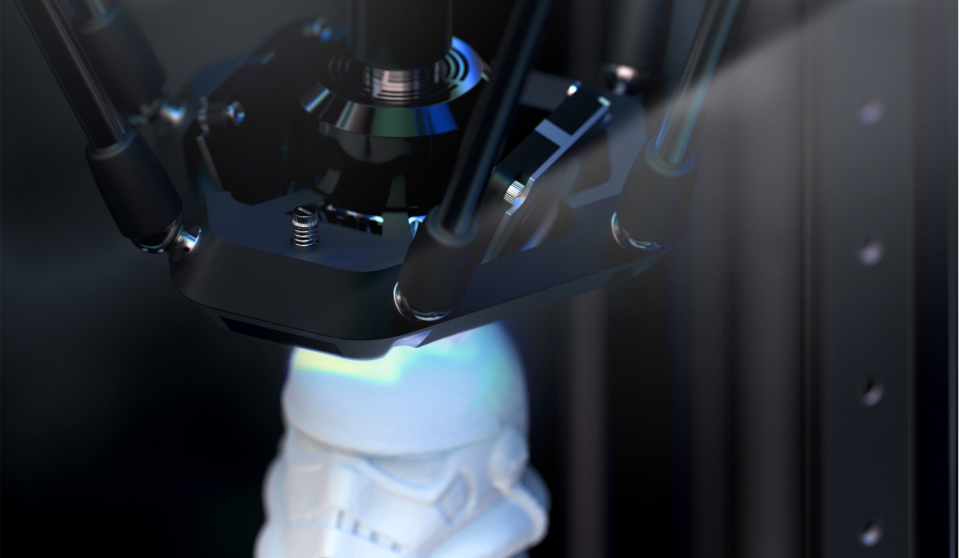

The team used two-photon polymerization 3D printing technology to cross-link raw material molecules, forming 3D nanostructures. Then, they were heated to 650 degrees Celsius in air to expel organic components and melt inorganic components to form quartz glass.

Using this process, researchers have printed several different nano glass structures, including "firewood piles" and "scaffolding" formed by stacking nano columns, parabolic shaped lenses, and cylinders with patterns engraved on both the outside and inside. These glass structures not only have precise structures, but also superior optical and mechanical properties, with strong resistance to high temperatures and chemical substances. The relevant paper was published in the American journal Science.